3D Printing

Definition

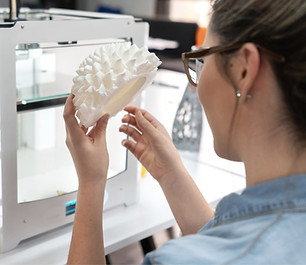

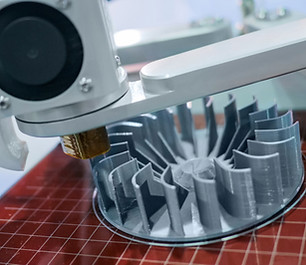

3D printing is an additive technology used to manufacture parts. It is ‘additive’ in that it doesn’t require a block of material or a mold to manufacture physical objects; it simply stacks and fuses layers of material. It’s typically fast, with low fixed setup costs, and can create more complex geometries than ‘traditional’ technologies, with an ever-expanding list of materials (3D printing technology, n.d.). Only the necessary number of materials used to create each layer is deposited from the printer; therefore, 3D printing is the opposite of traditional, subtractive manufacturing, which cuts away unnecessary material to create the desired shape (Berman, 2012). 3D printing allows for customization and is suited for one-off production. 3D printers are being used for mass-customized products such as medical and dental parts, replacement parts for electronics and appliances, architectural models, and sports equipment (Berman, 2012). The 3D printing process was devised in the 1980s and was originally known as ‘rapid prototyping’. It enabled companies to develop prototypes quickly and more accurately than with other methods (Roberson, 2021). However, in 2004, professor Adrian Bowyer of the University of Bath introduced the open-source 3D printer named RepRap. He applied fused-filament fabrication, a similar process to fused-deposition modeling (FDM) to produce the prototypes as well as commercially viable products (Chakraborty & Biswas, 2020).

The following video explains what 3D printing is, how it works, and what you need to get started.

Source. BCN3D (2023)

Today, 3D printing has wide usage in many manufacturing industries, like the production of mineral products, rubber, plastics, machinery equipment, and the construction industry. Check out this article to watch a video on 3D printing used in architecture to create a bridge.

Process of 3D Printing

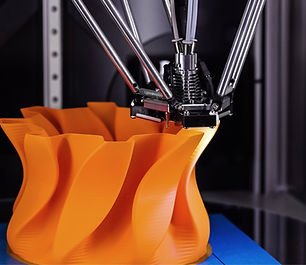

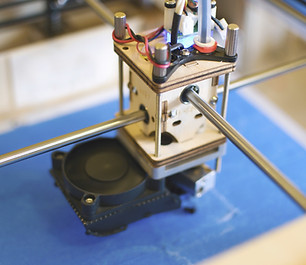

As mentioned, the 3D printing process involves building up layer upon layer of molten plastic to create an object. As each layer sets, the next layer is printed on top and the object is built up. To make a 3D print, a digital file is needed that tells the 3D printer where to print the material. This file essentially contains ‘coordinates’ to guide the printer’s movements in the 3D space along X, Y, and Z coordinates. 3D printers can print these layers at different thicknesses, known as layer height. A bit like pixels on a screen, more layers in a print will give a higher ‘resolution.’ This will give a better-looking result, but takes longer to print (Roberson, 2021). To transform a 2D design into a 3D product, digital 3D computer-aided design (CAD) software (such as Rhino, Materialise’s Magics software, Repetier-Host software, AutoCAD, and 3Ds Max) is used to create the design model, which is then virtually sliced into the appropriate number of horizontal layers needed to complete the product. The software divides the object into horizontal layers. The data from the file are then communicated to the printer (Vanderploeg et al., 2016). After the object is printed, it may need sanding and polishing to improve the surface finish and diminish the look of print lines. Color can also be modified via painting or dyeing.

The following video explains what 3D printing is.

Source. Tech Talk (2017)

3D Printing in Textile and Apparel Industry

3D printing is being used in the textile and apparel industry by numerous fashion retailers and designers for 1) prototypes, 2) customized products, and 3) artistic pieces. On the runway, haute couture designers (e.g., Francis Bitonti, Iris Van Herpen) have shown intricate, 3D-printed dresses and accessories (Vanderploeg et al., 2016). In addition, retailers, such as Timberland and Nike use 3D printing to compare 3D prototypes with CAD drawings. Nike was able to shorten the time of prototyping and final production from 2-3 years to six months and redesigned their Vapour Laser Talon cleat with the use of 3D printing (Vanderploeg et al., 2016). Mass-market fashion brands are also using 3D printing to produce customized products for consumers (Nayak & Padhye, 2015). Designers like Ganit Goldstein have created unique pieces by combining embroidery craft methods with direct-to-textile 3D printing. With recent advancements in 3D printers, designers are able to produce breathable, fabric-like materials made of interlocked structures, resulting in lightweight and flexible products (Vanderploeg et al., 2016). DefeXtiles, a tulle-like textile was developed by MIT Media Lab graduate student Jack Forman by mistake, while trying to control a common 3D printing defect — the under-extrusion of polymer filament (Ham, 2020). 3D printing in the industry has seen rapid and wide-ranging developments in the last few years. The following figure is a snapshot of current developments in 3D printing in the industry and includes links provided for all the designers and brands listed: - Textiles including the links (DefeXTiles, Leather, and Space Fabric/NASA), - Accessories including the links (VIP Tie, Chanet Watches, XYZ Handbags, Nervous System Jewellery, Ganit Goldstein/Satori, and VOJD Studios), - Designer Apparel including the links (Iris Van Herpen, Julia Daviy, Travis Fitch/ threeASFOUR, Jessica Rosenkrantz, Anouk Wippretch, ZER, Julia Korner, Zac Posen, Sylvia Heisel, Ganit Goldstien, Samual Canning & Melinda Looi, Tailor Mark, Sharecloth, and Zap&Buj), - Footwear including the links (Adidas Futurecraft 4D, Ecco Quant U, Reebok Liquid Factory, Nike Flyprint, Annie Foo, and Ica & Kostika), - Jackets including the links (Ministry of Supply and Danit Peleg), and - Mink Makeup including the links (Makeup and Bra)

Figure

Snapshot of Current Developments in 3D Printing in T&A Industry

FOOTWEAR

ACCESSORIES

Impact of 3D Printing in Textile and Apparel Industry

3D printing has had a disruptive impact on the industry. A conceptual model that summarizes the impact of 3D printing on the landscape of the industry focuses on four fundamental impacting components that include 1) design and product development, 2) supply chain/business structure, 3) sustainability, as well as 4) the new paradigm of integrating direct digital manufacturing (DDM) (Sun & Lu, 2015).

Design and Product Development

In design and product development the designer would be able to virtually interact with the product in a 3D CAD program and eliminate traditional processes like construction. 3D scanning technology could be employed to eliminate the human avatar required in the garment fitting stage of product development (Sun & Lu, 2015). 3D printing is part of the larger influence of 3D technology on apparel designing and simulation to create personalized products. For example, a 3D scanned foot model is used for extracting anthropometric data. This model is converted to a personalized last for footwear design. This personalized last, realized by 3D printing technology, is used for shoe production (Spahiu et al., 2016). Australian company Tailors Mark is using 3D printed, life size body replicas to get the right shape and fit of a tailored suit (Ahmed, 2019). Further the concept of bespoke design for individuals and co-designing with individuals outside the industry could become a new trend (Sun & Lu, 2015). Designer Ganit Goldstein ‘WeAreAble’ collection showcases garments created with a combination of handcrafted methods and 3D printing made based on measurements from a 360-degree body scanner, enabling her to create bespoke items. In comparison to garments, direct and indirect 3D printed jewelry has more material options, for example, metals and precious metals. The final metal or polymer parts can be produced using both direct and indirect 3D printing processes. Jewelry can be fabricated using almost any 3D printing techniques (Yap & Yeong, 2014).

Supply Chain and Business Structure

3D printing facilitates fundamentally different product development and production processes, types of inputs required and patterns of consumption. Because 3D printing (3DP) is highly technology and capital intensive, with little involvement of low-skilled labor, developed countries rather than developing countries may enjoy the comparative advantage in apparel manufacturing in the future. 3D printing technology will also initiate a new business model in which consumers can be empowered to self-fabricate the final product; thus, it can also potentially lead to some alternative distribution channels and new supportive services (Sun & Lu, 2015). A San Francisco-based start-up, Continuum, made an attempt at this by allowing its customers to design bikinis specifying their body shape and measurements on their website, and then used nylon to print out each order.

Sustainability

The above two factors mentioned can result in a reduced carbon footprint, and immense energy saving. Also, due to the 3D printing’s ability to build objects in only those places where the materials are needed, production waste or by-products can be reduced, much like the concept of minimal waste design. In many 3D printing processes, the technology allows the reuse of a wide range of materials, of which some are eco-friendly (Kreiger et al., 2014). These measures will add substantially to all aspects of a sustainable society (Sun & Lu, 2015). Julia Daviy’s zero-waste 3D printed clothing collection of fully customizable skirts are a step in this direction. With a patented technology that uses 100% recyclable filaments, Julia and her team can not only create highly customizable 3D printed garments but also create apparel with zero-waste for a cleaner and more sustainable world (Meyer, 2020). Pasricha and Greeninger (2018), have used design as a research paradigm to apply zero-waste principles to 3D printing in efforts to ensure sustainable applications of 3D technology in the fashion industry, demonstrating progress and interest in this area.

Direct Digital Manufacturing (DDM)

The above impacts would ultimately lead to the development of a new paradigm integrating direct digital manufacturing (DDM), which enables 3D physical parts to be produced directly from CAD file (Sun & Lu, 2015). In the past, when designers planned to manufacture a dress, they had to do so in bulk quantities to make the cost of production worthwhile. However, 3D printing has reduced the designers’ manufacturing costs to zero until an order has been received. This has facilitated the designers’ ability to experiment in small batches and sell the apparel in limited editions. Famous designers such as Catherine Wales (British), Michael Schmidt (German) and Iris Van Herpen (Dutch) have been using this technique to fabricate personalized clothing. Techniques to fabricate soft and flexible textiles and the introduction of parameters that enable users to design their own textile variations are further developments in this direction (Takahashi & Kim, 2019). The combination of 3D printing with a traditional soft textile fabric is another popular research area (Chakraborty & Biswas, 2020). Smart clothing laced with sensors is another innovation from the 3D printing process. For example, Hexoskin, a smart garment, can monitor not only heart rate, HRV, and breathing rate but also usual activities such as steps, cadence, positions, sleep etc. The sensors paired with a smart phone via Bluetooth, help to get real time data using third-party applications. Another smart garment named “Athos Smart Clothes” can monitor real time muscle activity, heart rate, and calorie expenditure (Chakraborty & Biswas, 2020).

Types of 3D Printing

The five 3D printing methods most applicable to fashion products are: Stereolithography (SL), Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), PolyJet, and Binder Jetting (Vanderploeg et al., 2017).

Stereolithography (SL)

A stereolithography apparatus (SLA) consists of four main components: a tank filled with photopolymer resin, a building platform that descends into the tank, the UV laser, and a computer that controls the platform and laser (Sclater, 2011). SLA 3D printing uses a UV-curable resin as raw material. The resin is poured into a glass-bottomed container, into which a build platform is submerged. A laser shines UV light on the resin to selectively harden a cross-section of the required shape. The platform gradually raises out of the container to build up the print (Roberson, 2021). To begin the process, the first thin layer of photopolymer resin is exposed above the building platform. After the first layer is completed, the building platform is lowered, exposing the next layer of photopolymer resin. Once the laser traces the second layer, it is bonded to the top layer, continuing until the product is finished (Hoskins, 2013; Sclater, 2011). SL is a relatively fast printing process with the product printing in a few hours (Sclater, 2011). SL is also relatively user-friendly, allowing inexperienced designers to create detailed pieces with a high-quality surface finish (Huang et al., 2012). The disadvantage is that the process requires support rafts which are removed after completion. This process requires time and can affect the quality of the final product (Huang et al., 2012; Sclater, 2011). Other disadvantages are lack of color variety and cost of print material (Huang et al., 2012). Dutch designer, Iris van Herpen, used Materialise’s Mammoth SL printer for her Wilderness Embodied Collection. The collars and spiky elements on the dresses were designed in collaboration with architect Isaie Bloch and 3D-printed with additive manufacturing company Materialise (Howarth, 2013). The garment featured a hybrid semi-transparent dress made of hand-crafted elements and thin, bone-like, transparent pieces created with SL. Other examples of dresses created with Mammoth are Lady Gaga’s Anemone dress with incorporated bubble factory and Parametric Sculptured Dress (Vanderploeg et al., 2016). More recently, fashion designer Ganit Goldstein produced a collection of necklaces using this technology in collaboration with Satori, a UK-based 3D printing start-up that launched its ST1600 Masked Stereolithography system (Davies, 2021).

See Images in the Following Links:

Selective Laser Sintering (SLS)

SLS 3D printing uses a powdered raw material, typically a polymer. The powder sits in a container, where a blade distributes a thin layer of material onto the build area. A laser fuses the small particles of material together to form a single horizontal layer of the part, then the container moves a fraction of a millimeter to start a new layer, and the blade swipes across the build area to deposit a new layer of raw material. This process repeats to create the finished object (Roberson, 2021). A computer-controlled laser traces the layer, heating the powder to just below its boiling point to fuse the particles into a solid object, which is known as sintering (Huang et al., 2012; Sclater, 2011). A benefit of SLS is that it allows designers to create delicate, yet highly functional and durable products with a wide variety of available materials. Also the process does not use support rafts (Sclater, 2011). A disadvantage of SLS is that it does not produce a high-quality surface finish compared to SL (Huang et al., 2013; Sclater, 2011). The following video is a short demonstration of the process. Designer Iris Van Herpen, one of the pioneering and prolific users of 3D printing technology in fashion, used the SLS technique in her Voltage collection in 2013. The piece’s intricate lace-like texture was created with precision by SLS (Iris van Herpen Debuts Wearable 3D Printed Pieces at Paris Fashion Week, 2013). Dutch designer Anouk Wippretch has designed the Proximity Dress, using proximity and thermal sensors, that creates physical barriers when a person is detected in the immediate surroundings of the wearer. Each dress extends itself using a robotic 3D-printed hip mechanism built into the dress and a resin 3D-printed transparent collar with integrated sensors. The hip mechanisms holding the servos to the mechanic hip parts are 3D printed using SLS nylon PA-11 to endure more stresses. The 3D printed transparent collar, which has a more aesthetic use, is 3D printed using an Objet Connex 500 multi-material polyjet 3D printer and the VeroClear material from Stratasys (Sher, 2020). Another example is watchmaker Hoptroff Ltd. of London, who used the direct metal laser sintering (DMLS) method to 3D print their watch cases from actual gold (Molitch-Hou, 2013). It was made using SLS printer EOS’s PRECIOUS M 080, which is specifically used for the production of high-quality metal jewelry and watches. It is highly compatible with jewelry and watch designer work environments, as it is small, user-friendly, and appropriate for office spaces (Vanderploeg et al., 2016). Selective laser melting (SLM) is a technique in which a high-powered laser beam is selectively directed to the powder surface and the powder particles to melt and form solid metal.

The following video explains how an SLS printer works.

Source. Hamy T (2018)

See Images in the Following Links:

Fused Deposition Modelling (FDM)

The FDM (also called Fused Filament Fabrication, FFF) process involves extruding a thick string of material, commonly referred to as filament, through a heated nozzle. The nozzle is mounted on a motion system that moves it around a build area, where the melted filament is deposited onto a build plate. As the material cools and solidifies, the build plate moves down by a fraction of a millimeter layer by layer until the object is complete (Roberson, 2021). FDM is commonly used, as it is relatively affordable and offers a variety of low-cost desktop printers (Leigh et al., 2012). It can be used to print glossy, lace-like fabrics. However, the disadvantage is visible seam lines in between layers. FDM requires support rafts, which must be mechanically broken off or dissolved in detergent. Also, as the temperature fluctuates inside the printer during production, it may influence the strength of the bond between layers (Huang et al., 2013). Francis Bitonti led a workshop at his studio in which students experimented with digital modeling and 3D-printing technologies, resulting in the creation of the Bristle Dress and the Verlan Dress (Howarth, 2014) (Howarth, 2013b). He used MakerBot’s Replicator 2 Desktop Printer to develop the designs. The upper part of the dress was designed to be 3D printed in MakerBot Natural PLA Filament (clear), selected for its translucent qualities. The skirt was created using MakerBot Flexible Filament (MakerBot & Designer, 2014). Researchers have developed different weaves and knitted structures, such as woven fabric structures with visible stitches and weft-knitted structures, using the FDM process. They have also been successful in developing garment panels, lace structures, and composite structures employing FDM printing (Chakraborty & Biswas, 2020). Israeli designer Danit Peleg used FDM printing to create an entire collection using desktop 3D home printers for her graduate project at Shenkar College of Engineering and Design. She says, “I believe and hope that by 2030, the way we manufacture our clothes will change dramatically, and with 3D printing, I believe we have a shot at reinventing this industry and rebuilding it to be circular and radically cleaner” (Press Kit, n.d.). The designer also runs workshops on 3D printing for hobbyists and consumers.

See Images in the Following Links:

Polyjet

PolyJet is a type of material jetting technology that uses UV light or heat to harden photopolymers, metals, or wax, building parts one layer at a time (3D printing technology, n.d.). It allows multiple materials to be deposited in a single layer (Sclater, 2011). PolyJet uses drop-on-demand inkjet printing to selectively drop beads of liquid photopolymer resin from inkjet print heads onto a building platform. Subsequently, a roller evens out the surface of the layer. Two UV lights, one following another, pass over the layer multiple times to harden the liquid resin. To make room for the next layer, the building platform lowers, continuing until the print is complete (Sclater, 2011). Polyjet is one of the fastest printing methods, offers a high-quality finish, and its greatest benefit is that it can print products made of multiple materials (Vanderploeg et al., 2016). However, it requires support rafts that need to be mechanically removed and exposure to ambient heat, humidity, or sunlight can lead to a dimensional change in the product (Meisel et al., 2014). Iris Van Herpen’s Voltage collection included ensembles printed by Objet Connex polyjet printers from Objet Geometries. The pieces were printed with a variety of materials, incorporating both hard and soft elements, providing the movement and texture of the garments. Fashion designers three ASFOUR and Travis Fitch designed their dresses – ‘Pangolin’ and ‘Harmonograph’ using Stratasys’ multi-color Connex3 3D printer. Pangolin is made from 14 pattern pieces, and consists of a four-dimensional stretch – up and down, left and right, forwards and backward. Inkjet printing is also widely used in making electronic textiles, where the sensors or circuits are printed on the textile fabric (Chakraborty & Biswas, 2020).

See Images in the Following Links:

Binder Jetting

Binder jetting uses an industrial printhead to deposit a binding adhesive agent onto thin layers of powder material. Unlike other 3D printing technologies, binder jetting does not require heat (3D printing technology, n.d.). To begin the process, the powder materials are spread in a thin layer onto a building platform. An inkjet print head deposits the glue material onto the layer of powder to complete the first layer (Gibson et al., 2021). The building platform lowers to make room for the next layer of powder materials (Gibson et al., 2015). With each new bonded layer, the unused powder is removed (Huang et al., 2013). This process continues until the product is finalized (Sclater, 2011). Binder jetting printing does not need support rafts and is the fastest of the 3D printing methods. It is the only 3D printing method to print in multiple colors simultaneously (Hoskins, 2018). However, it produces a weaker product and may provide an uneven surface finish (Huang et al., 2012). The Timberland Company uses Spectrum Z510 to develop prototypes for comparison with 2D CAD drawings in their footwear division. Color prototypes offer a more realistic perception of the end product. Prototypes now take $35 and 90 minutes to make vs. $1200 and one full week (DEVELOP3D, 2008). 3D printing technology is undergoing a rapid innovation phase. New technologies are emerging and corresponding support products and services are developing. In 2016, Nike leveraged the potential of 3D printing by partnering with Hewlett-Packard (HP). HP invented and developed the Multi Jet Fusion (MJF) Technology. MJF is similar to binder jetting. It uses a powdered material, a binding agent, but does not require lasers. Print quality and detailing have confirmed the potential of the technology, and according to some industry experts, this technology is likely to lead the 3D printing revolution.

Nike developed a 3D-printed track spike, the Nike Zoom Superfly Flyknit.

Following is a table categorizing printing technologies used by some prominent designers/brands with 3D printer models and companies mentioned (where information is available).

Table

Prominent designers/brands with 3D printer models and companies

Challenges and Consumer Reactions

One of the main barriers to the wide adoption of 3D technology in the industry is its limitation in material choice. The synthetic filament used in this technology produces stiff and rigid clothing. Most materials used in 3D printing are made of man-made filament, which has an unsustainable manufacturing process. These materials do not have any simple method of being disposed of and recycled (Chakraborty & Biswas, 2020). Moreover, the raw materials are very expensive, which can discourage their usage for mass production. Designers may find it limiting to depend on expensive 3D printers such as an SLA or SLS that produce basic chainmail fabrication most of the time. Further creation of multi-color designs is hindered by the limited availability of filament materials (Chakraborty & Biswas, 2020). Designers today will also need to develop skills in applying 3D CAD and translating traditional training knowledge into virtual design environments. Also, issues such as unskilled labor management and updating current legal systems for intellectual property protection need to be addressed (Sun & Lu, 2015). Studies on consumer reactions to 3D printing reveal that while many believe 3D printed apparel has several advantages, like customization, these were not the reasons for buying; while the disadvantages (like not comfortable to wear, not breathable) were the reasons for not buying 3D printed products. Consumers were more interested in 3D-printed accessories than garments because 3D-printed accessories are cheaper and offer greater comfort and ease of movement than 3D-printed garments. In other words, consumers are willing to wear plastic bracelets, but do not necessarily want to wear a pair of plastic pants (Perry, 2017).

References

Ahmed, R. (2019, September 18). Tailors mark 3D prints customers’ bodies for a perfect fit. 3D printing.com. https://3dprinting.com/fashion/tailors-mark-3d-prints-customers-bodies-for-a-perfect-fit/

BCN3D (2023, March 22). BCN3D explains: The beginner's guide to 3D printing. [Video]. YouTube. https://www.youtube.com/watch?v=e350tZJNxvI

Berman, B. (2012). 3-D printing: The new industrial revolution. Business Horizons, 55(2), 155–162.

Best foot forward. (2008, October 27). DEVELOP3D. Retrieved October 1, 2021, from https://develop3d.com/prototype/best-foot-forward/

Bojovic, M. (2014, February 21). 3D printed dresses: A new fashion trend. eVolo. https://www.evolo.us/3d-printed-dresses-a-new-fashion-trend/

Chakraborty, S., & Biswas, M. C. (2020). 3D printing technology of polymer fiber composites in textile and fashion industry: A potential roadmap of concept to consumer. Composite Structures, 248, 1-14.

Davies, S. (2021, February 10). Ganit Goldstein teams with Satori to 3D print new necklace collection. TCT Magazine. https://www.tctmagazine.com/additive-manufacturing-3d-printing-news/ganit-goldstein-satori-3d-print-new-necklace-collection/

Flexible 3D printed fashion hits the catwalk with Iris van Herpen, Julia Koerner and Materialise. (n.d.). i.materialise. https://i.materialise.com/blog/en/flexible-3d-printed-fashion-hits-the-catwalk-with-iris-van-herpen-julia-koerner-and-materialise/

Ganit Goldstein combines 3D printing & embroidery to create sustainable custom garments. (2020, December 15). Designboom. Retrieved October 1, 2021, from https://www.designboom.com/design/ganit-goldstein-3d-printing-embroidery-sustainable-custom-garments-10-30-2020/

Gibson, I., Rosen, D., & Stucker, B. (2015). Additive manufacturing technologies: 3D printing, rapid prototyping, and direct digital manufacturing. Springer-Verlag, New York.

Gibson, I., Rosen, D., Stucker, B., & Khorasani, M. (2021). Binder jetting. In Additive manufacturing technologies (2nd Eds.), 3D printing, rapid prototyping, and direct digital manufacturing (pp. 237-252). Springer, Cham.

Grunewald, J. S. (2016, April 27). Nike’s 3D printed sprinting shoe the Zoom Superfly Flyknit will be worn at the 2016 Olympic games in Rio. 3Dprint.com. https://3dprint.com/131549/nike-zoom-superfly-flyknit/

Ham, B. (2020, October 6). Leveraging a 3D printer “defect” to create a new quasi-textile. MIT News | Massachusetts Institute of Technology. https://news.mit.edu/2020/defextiles-leveraging-3d-printer-defect-to-create-quasi-textiles-1020#

Hamy T (2018, December 18). Naenae computer clubhouse's phantom 3 legs printed on SLS printer. [Video]. YouTube. https://www.youtube.com/watch?v=pAvOLbXbIIY

Hoskins, S. (2018). 3D printing for artists, designers, and makers. London Bloomsbury Publishing.

Howarth, D. (2013a, August 6). Wilderness embodies by Iris Van Herpen. Dezeen. https://www.dezeen.com/2013/08/06/wilderness-embodied-by-iris-van-herpen/

Howarth, D. (2013b, September 24). Verlan 3D-printed dress by Francis Bitonti. Dezeen. https://www.dezeen.com/2013/09/24/verlan-3d-printed-dress-by-francis-bitonti/

Howarth, D. (2014, March 10). Francis Bitonti and students 3D-print flexible dress on a makerbot. Dezeen. https://www.dezeen.com/2014/03/10/francis-bitonti-and-new-skins-workshop-students-3d-print-flexible-dress-on-a-makerbot/

Huang, S. H., Liu, P., Mokasdar, A., & Hou, L. (2012). Additive manufacturing and its societal impact: A literature review. The International Journal of Advanced Manufacturing Technology, 67(5-8), 1191–1203.

Iris Van Herpen presents Iris Van Herpen X Neri Oxman. (n.d.). Irisvanherpen.com. Retrieved October 1, 2021, from https://www.irisvanherpen.com/news/mad-museum-ny-exhibition-iris-van-herpen-x-neri-oxman

Iris Van Herpen presents her Wilderness Embodied Collection. (n.d.). i.materialise. https://i.materialise.com/blog/en/iris-van-herpen-presents-her-wilderness-embodied-collection/

Kreiger, M. A., Mulder, M. L., Glover, A. G., & Pearce, J. M. (2014). Life cycle analysis of distributed recycling of post-consumer high-density polyethylene for 3-D printing filament. Journal of Cleaner Production, 70, 90–96.

Leigh, S. J., Bradley, R. J., Purssell, C. P., Billson, D. R., & Hutchins, D. A. (2012). A simple, low-cost conductive composite material for 3D printing of electronic sensors. PLoS ONE, 7(11), 1-6.

MakerBot and designer Francis Bitonti collaborate on new skins workshop to create fabulous 3D printed dress. (2014, March 12). Businesswire. Retrieved October 1, 2021, from https://www.businesswire.com/news/home/20140312006034/en/MakerBot-and-Designer-Francis-Bitonti-Collaborate-on-New-Skins-Workshop-To-Create-Fabulous-3D-Printed-Dress

McKnight, J. (2016, February 17). Fashion label threeasfour unveils two 3D-printed dresses for biomimicry collection. Dezeen. https://www.dezeen.com/2016/02/17/3d-printed-dresses-threeasfour-new-york-fashion-week-2016/

Meisel, N. A., Elliott, A. M., & Williams, C. B. (2014). A procedure for creating actuated joints via embedding shape memory alloys in PolyJet 3D printing. Journal of Intelligent Material Systems and Structures, 26(12), 1498–1512.

Meyer, M. (2020, December 3). The world’s first fully customizable zero-waste 3D printed skirt. Thevou.com. https://thevou.com/fashion/3d-printed-clothing/

Molitch-Hou, M. (2013, September 2). The first commercial watch made from 3D printed gold. 3D Printing Industry. https://3dprintingindustry.com/news/the-first-commercial-watch-made-from-3d-printed-gold-16383/

Nayak, R., & Padhye, R. (2015). Introduction: The apparel industry. In Garment manufacturing technology (pp. 1-17). Woodhead Publishing.

News | Mad Museum NY Exhibition, Iris Van Herpen X Neri Oxman. (n.d.). Iris Van Herpen. Retrieved October 1, 2021, from https://www.irisvanherpen.com/news/mad-museum-ny-exhibition-iris-van-herpen-x-neri-oxman

Parkes, J. (2021, July 28). Zaha Hadid Architects and ETH Zurich create 3D-printed concrete bridge in Venice Dezeen. https://www.dezeen.com/2021/07/28/zaha-hadid-architects-block-research-group-straitus-3d-printed-concrete-bridge/

Pasricha, A., & Greeninger, R. (2018). Exploration of 3D printing to create zero waste sustainable fashion notions and jewelry. Fashion and Textiles, 5(1), 30.

Perry, A. (2017). 3D-printed apparel and 3D printer: Exploring advantages, concerns, and purchases. International Journal of Fashion Design, Technology and Education, 11(1), 95–103.

Press Kit. (n.d.). Danit Peleg. Retrieved October 1, 2021, from https://danitpeleg.com/press-kit/

Roberson, D. (2021, May 21). What is 3D printing? Everything you need to know. Ultimaker.com. https://ultimaker.com/learn/what-is-3d-printing

Saunders, S. (2020, June 2). Anouk Wipprecht’s 3D printed proximity dresses are perfect for social distancing. 3Dprint.com. https://3dprint.com/268227/anouk-wipprecht-3d-printed-proximity-dress-is-perfect-for-social-distancing/

Sclater, N. (2011). Mechanisms and mechanical devices sourcebook. Mcgraw-Hill Education.

Sharma, R. (2013, December 6). Lady Gaga goes Gaga over 3D printing. Forbes. https://www.forbes.com/sites/rakeshsharma/2013/12/06/lady-gaga-goes-gaga-over-3d-printing/?sh=3618522e1680

Sher, D. (2020, May 27). Anouk Wipprecht presents new 3D printed proximity dress for social distancing. 3D printing media network - the pulse of the AM Industry. https://www.3dprintingmedia.network/anouk-wipprecht-social-distancing-proximity-dress/

Spahiu, T., Piperi, E., Grimmelsmann, N., Ehrmann, A., & Shehi, E. (2016, November). 3D printing as a new technology for apparel designing and manufacturing. In International Textile Conference, Dresden, Germany.

Sun, L., & Lu, S. (2015). The 3D printing era: A conceptual model for the textile and apparel industry. International Textile and Apparel Association Annual Conference Proceedings, 72(1).

Takahashi, H., & Kim, J. (2019). 3D printed fabric. Proceedings of the 32nd Annual ACM Symposium on User Interface Software and Technology, 43–51.

Tech Talk (2017, March 6). What is 3D printing?. [Video]. YouTube. https://www.youtube.com/watch?v=9hRhVGfyPrM

Vanderploeg, A., Lee, S.-E., & Mamp, M. (2017). The application of 3D printing technology in the fashion industry. International Journal of Fashion Design, Technology and Education, 10(2), 170–179.

What is 3D printing? (n.d.). Hubs. Retrieved October 1, 2021, from https://www.hubs.com/guides/3d-printing/#chap

What is FDM 3D printing? – simply explained. (2022, August 12). Foxdoc. Retrieved May 1, 2024, from https://facfox.com/docs/kb/what-is-fdm-3d-printing-simply-explained

Yap, Y. L., & Yeong, W. Y. (2014). Additive manufacture of fashion and jewellery products: A mini review. Virtual and Physical Prototyping, 9(3), 195–201.